SERVICE SCOPE

We have been in the glassware business for 13 years and have built a reputation for producing top-quality products. We have a wide variety of glassware and ceramic dinnerware options available to suit any need, from wine glasses and tumblers to shot glasses and beer mugs,and wedding charger plate, bowls and dinnerware set.

Production

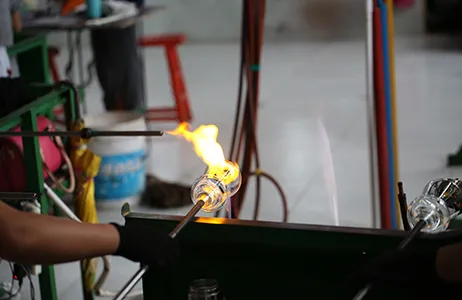

In combination with nearly all glass deep-processing processes, such as manual blowing and painting, electroplating, flower baking, gold baking, sanding, electro-light water, acid washing, flower grinding, carving, etc., all kinds of glassware, such as wine glasses, vases, water glasses, storage tanks, are produced.

Wholesale

According to our years of business experience and the needs of our customers, our company has a large number of classic best-selling products, which is convenient for small wholesalers to purchase directly, which not only saves production time, but also provides convenience for our customers.

Research and development

Our company has a high-quality professional research and development team that has been engaged in glassware research and development for many years, with strong technical force, and has a number of qualified software and hardware engineers, professional product development designers

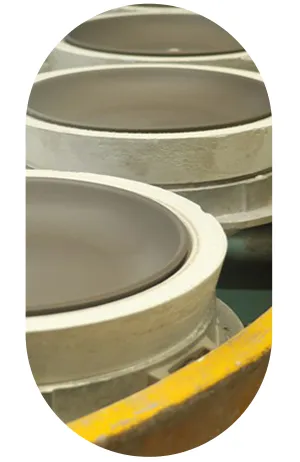

PRODUCTION PROCESS

At Sanzo, we understand that every customer has unique needs and preferences. That’s why we offer a range of customization options for our glassware and ceramic products.

PRODUCT CUSTOMIZATION

Our team of experts is dedicated to ensuring that every product we produce meets our high standards. We use only the best materials and manufacturing processes to create glassware and ceramic dinnerware that is not only beautiful, but also durable and long-lasting.

At Sanzo, we understand that every customer has unique needs and preferences. That's why we offer a range of customization options for our glassware and ceramic products. We can add your company logo or design to create a personalized look, or we can work with you to create a completely unique design from scratch,we are not only one glassware and ceramic dinnerware manufacturer and supplier, but also one professional designer which help realize your dream.

POST-PROCESSING PROCESS DISPLAY II

The products cover the domestic market with its excellent quality and are exported to Europe, North America and other developed countries and developing countries in Southeast Asia, Africa, the Middle East and so on.

POST PROCESSING DISPLAY

The products cover the domestic market with its excellent quality and are exported to Europe, North America and other developed countries and developing countries in Southeast Asia, Africa, the Middle East and so on.